Difference In Design

Design Differences

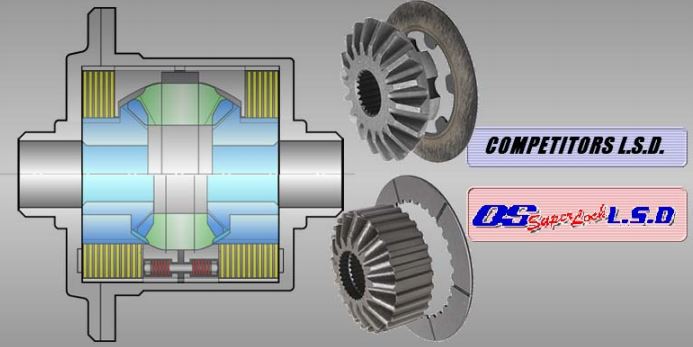

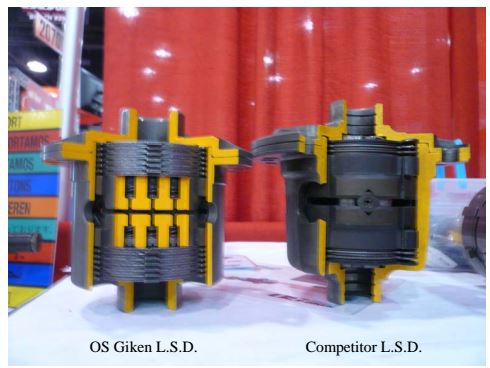

“TRADITIONAL” Clutch-type L.S.D. (competitors versions)

- Typically use cast components, no heat treatment

- Larger pressure ring limits space for disks

- Less rigid side gears

- Less plate capacity

- No progressive locking ability

- Less surface area on disks

- Disks are typically manufactured with a larger manufacturing variance

- No relief on the case for cone springs

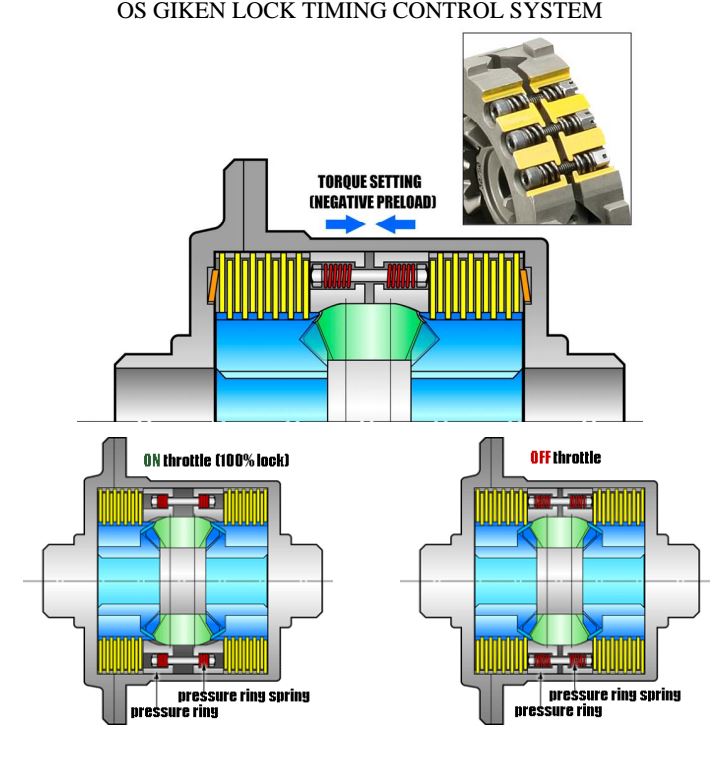

OS Superlock differential lock

OS Seperlock L.S.D.

Performance Differences

Break-in procedure required: usually consists of doing figure-8s in an empty lot for 30 minutes. Since 100% lock capability is not possible, the friction created by the plates generates high levels of heat, which essentially wear down the plates so that they can seat to each other properly. (Lower manufacturing tolerances for the plates result in variances in shape, thickness, etc.) This type of break-in procedure may lead to uneven wear between the left and right side of the LSD.

Periodic Overhaul Required

Since these types of LSD cannot achieve true 100% locking, constant friction on the LSD components generates more heat which leads to additional wear or premature failure, necessitating periodic overhaul of LSD components.

Inconsistent Performance

Since these LSD’s already have driver-induced wear from break-in and continue to wear throughout the lifespan of the unit, actual locking performance diminishes the more the unit is used. More frequent fluid changes required: Due to the amount to friction created in the

LSD, additional heat is generated which leads to earlier break-down of the diff

fluid. Fluid changes are usually recommended every 5000-8000 miles for normal usage.

Inconvenient For Normal Street Driving

These types of LSD can only operate

within a certain range of lock capacity (e.g. 60% accel, 40% decel) and can be adjusted by increasing/decreasing the preload. Typically, preload is set on the higher side in order to achieve more lock capability, but comes at the cost of the unit locking at slower speeds. Normal behavior is for the wheels to “skip” through turns and to generate undesireable noise.